Expert Tahoe Instrument Cluster Repair: Restoring Accuracy to Your Gauges

Expert Tahoe Instrument Cluster Repair: Restoring Accuracy to Your Gauges

Blog Article

Ultimate Resource for Advanced Automobile Instrument Cluster Repair Methods

In the world of contemporary auto maintenance, the ins and outs of instrument cluster repair work stand as a crucial aspect of making certain the optimum functioning of a vehicle. By checking out the tools needed, typical troubles ran into, and step-by-step repair service techniques, one can furnish themselves with the understanding needed to navigate the complex globe of vehicle instrument collection repair service with confidence and precision.

Value of Advanced Tool Collection Repair Service

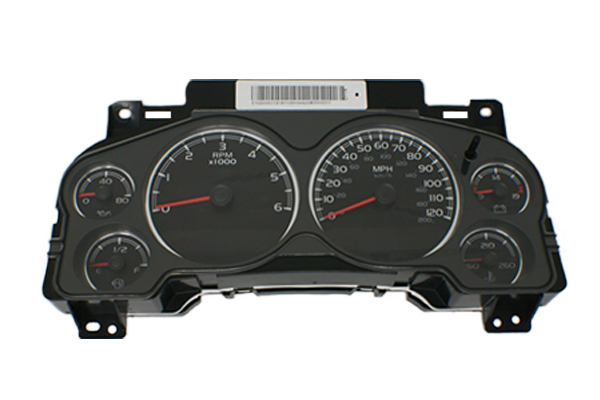

Understanding the importance of innovative instrument cluster repair is vital for maintaining the performance and precision of modern lorry systems. The tool cluster works as the hub of info for drivers, showing critical information such as rate, fuel levels, engine temperature, and warning indications. With the innovation of modern technology, tool clusters have developed to include complex electronic parts and digital screens, making repairs much more detailed and specialized.

Appropriate repair service and upkeep of the instrument collection are vital for making sure the safety and efficiency of the lorry. Problems with the instrument collection can lead to imprecise readings, breakdowns in crucial systems, and safety hazards when driving. Advanced tool collection fixing methods entail identifying digital faults, altering sensors, and reprogramming software application to recover ideal efficiency.

Tools and Tools Needed

To efficiently address the intricate fixing needs of modern automobile tool collections, a specialized set of tools and equipment is important. Some of the secret devices needed for advanced car instrument collection fixing consist of accuracy screwdrivers, trim elimination tools, soldering devices, digital multimeters, and diagnostic scanners. Accuracy screwdrivers are crucial for dismantling the cluster without triggering damage. Cut elimination devices aid in securely prying off bezels and panels. Soldering equipment is essential for fixing damaged connections or replacing elements. Digital multimeters are made use of to measure voltage, connection, and resistance throughout diagnostic treatments. Diagnostic scanners are important for recognizing and repairing electronic problems within the tool cluster. In addition, having a good high quality welding torch, desoldering pump, and solder wire is necessary for accomplishing detailed soldering work. Appropriate lighting, a magnifying glass, and a clean workspace are additionally essential for making certain precision and precision during fixings. By having these specialized tools and equipment available, technicians can effectively detect and fix intricate concerns in auto instrument clusters.

Common Issues and Solutions

Several usual problems often encountered in vehicle tool clusters can be efficiently resolved with targeted remedies. One widespread trouble is malfunctioning evaluates, which may result from a malfunctioning stepper electric motor. To resolve this, replacing the stepper electric motor can recover accurate gauge analyses. Another typical concern is dim or flickering lights on the tool cluster (tahoe instrument cluster repair). This can often be credited to a damaged light bulb or poor links. By replacing the light bulb or making sure secure connections, the lighting issue can be easily corrected. Additionally, a malfunctioning odometer or display screen is a frequent concern. This could be due to a malfunctioning display screen system that requires to be changed to restore appropriate capability. Periodic power or total failure of the tool collection might stem from a blown fuse or wiring issue. Monitoring and changing the fuse, as well as evaluating the wiring for any type of damages, can aid deal with these power-related troubles successfully. By identifying these typical issues and using the suitable options, car instrument collection performance can be brought back effectively.

Step-by-Step Repair Overview

A methodical approach to diagnosing and repairing car tool cluster concerns is crucial for achieving precise and reliable results. To start the repair service process, the initial action is to thoroughly check the instrument cluster for any kind of noticeable damages such as burnt-out bulbs, cracked displays, or loosened links.

Tips for Precautionary Upkeep

After carrying out an extensive diagnostic check and finishing essential repair services look at here now on the vehicle tool cluster, executing normal preventative maintenance actions is crucial to make sure long-lasting capability and optimal efficiency of the lorry's essential evaluates and indicators. To begin, it is crucial to consistently check the tool collection for any type of signs of wear, such as fading displays or malfunctioning lights. Keeping the cluster clean from dirt and particles can likewise stop damage to delicate parts. Furthermore, inspecting the connections and wiring for any indicators of corrosion or loose links can aid prevent electric issues that might influence the cluster's additional reading performance.

Moreover, upgrading the software of the instrument collection when essential can ensure compatibility with any kind of new features or systems in the automobile. It is additionally suggested to adhere to the manufacturer's recommended maintenance timetable and standards for the instrument collection to maintain its long life. By incorporating these preventative upkeep pointers right into your regular car treatment, you can assist extend the life expectancy and reliability of your automobile tool cluster.

Final Thought

Finally, innovative auto tool collection repair service techniques are necessary for maintaining the functionality of contemporary cars. By using the correct devices and look at here now equipment, addressing typical problems, and adhering to a detailed repair service guide, specialists can efficiently identify and repair instrument collection problems. Implementing preventative maintenance strategies can help prolong the life expectancy of the instrument cluster and stop future problems from arising.

By discovering the devices called for, typical issues came across, and step-by-step repair service methodologies, one can outfit themselves with the understanding needed to navigate the elaborate globe of car instrument cluster repair with self-confidence and precision.

An organized technique to fixing and diagnosing car tool cluster concerns is vital for attaining accurate and effective results. By following this detailed guide diligently, car professionals can successfully diagnose and fix tool cluster problems with precision and self-confidence.

In verdict, innovative vehicle instrument collection repair techniques are essential for keeping the performance of modern vehicles. By making use of the appropriate devices and devices, resolving typical issues, and adhering to a detailed repair work overview, service technicians can efficiently diagnose and fix tool collection problems.

Report this page